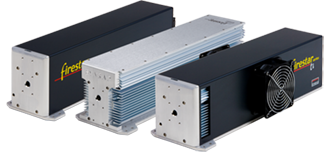

Precision Laser Processing

Micron-level accuracy, high repeatability, and reliable laser precision processing solutions

レーザー・アプリケーション

Experience micron-level accuracy with precision laser processing solutions by Novanta Photonics. Designed for high repeatability, our precision laser systems are fast, reliable, and incredibly versatile. Mark, code, drill, and modify industrial materials with extreme precision, consistency and quality.

Request an Application or Material Test

Request an Application or Material Test

What is precision laser processing?

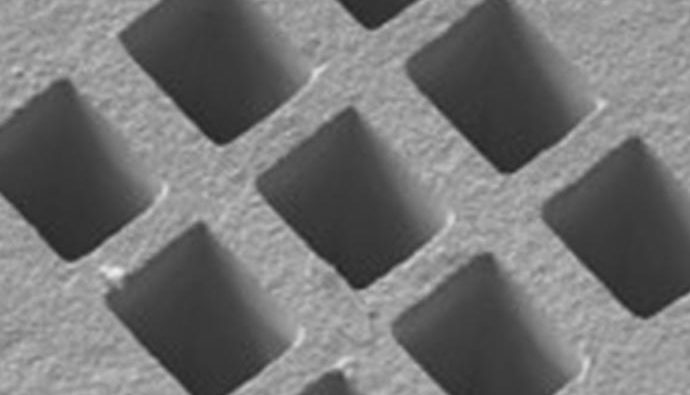

Precision laser processing encompasses a wide range of applications that share the common goal of accurately removing material, while carefully controlling:

- Shape

- Kerf

- Taper

- Heat impact

- Feature placement accuracy

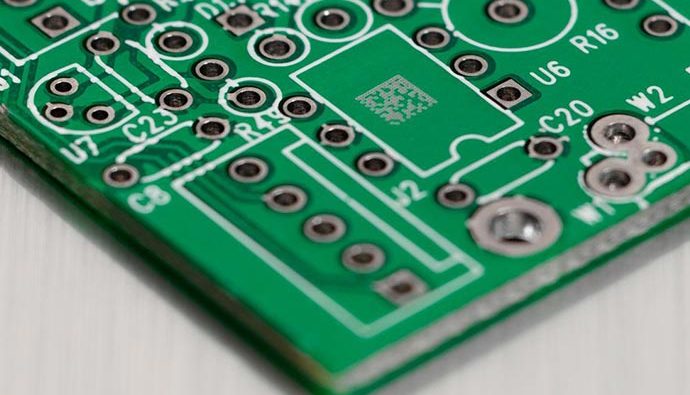

Precision laser services offer the level of control, quality, and versatility needed to meet manufacturing goals. Often, mechanical or traditional processes cannot replicate the complex, delicate work required in new and expanding application areas. Precision laser solutions enable micron-level accuracy while maintaining high throughput.

Lasers offer a non-contact method of processing sensitive materials, and no tool wear or replacement means results are consistent and repeatable over time. Precision laser systems are also highly versatile, offering a digitally controlled process that can be altered instantly as market and technology demands change.

Benefits of precision laser processing

The advantages of using precision laser processing services include:

- Faster processing: the repeatability of precision laser solutions enables fast, efficient processing, supporting overall efficiency. Explore ultrafast lasers for even greater speed

- Achieve micron-level precision: digitally controlled precision laser measurement enables a level of accuracy that traditional laser processes simply can’t achieve

- Efficiency: there’s no tool wear with precision laser processing and it’s highly repeatable, making it a more efficient process

- Consistency: lasers only need to be programed once in order to deliver high repeatability and precise, consistent results

- Versatility: use precision laser solutions to process metals, plastics, ceramics, glass, thin film, leather, cardboard, paper, textiles, and more

- Durability: precision laser systems can create permanent marking and coding, including barcodes, serial numbers and expiration dates, supporting traceability and safety

- Cost-effective: with no tool wear or replacement supporting increased productivity and minimal waste, precision laser services can be a cost-effective solution

Why choose Novanta Photonics for precision laser services?

Novanta Photonics has over 35 years’ experience in developing precision laser solutions for customers across the globe. Our extreme precision laser processing systems incorporate market-leading beam steering delivery and software to keep your business flexible and efficient as industrial applications continue to evolve.

Request an Application or Material Test

Request an Application or Material Test

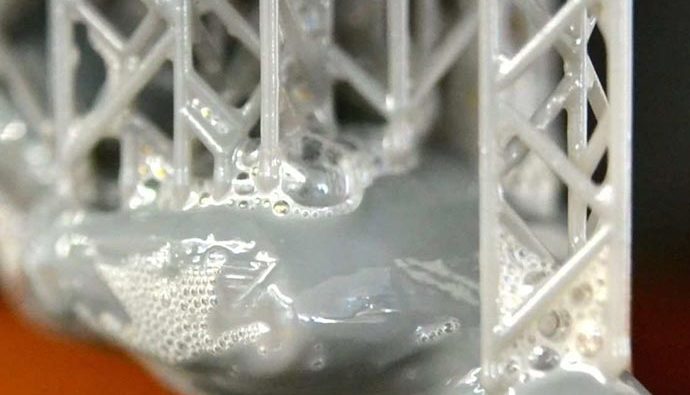

Precision Laser Processing Applications

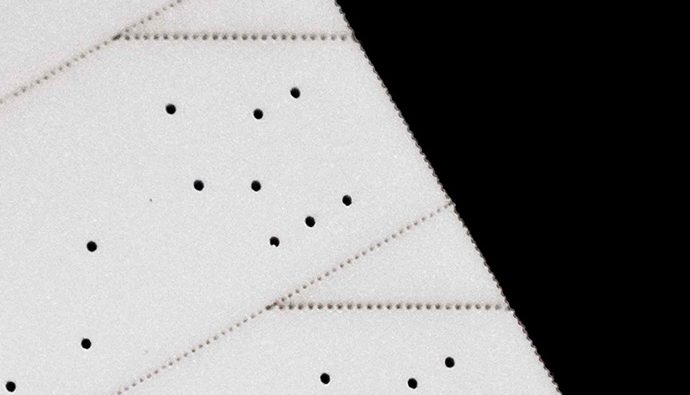

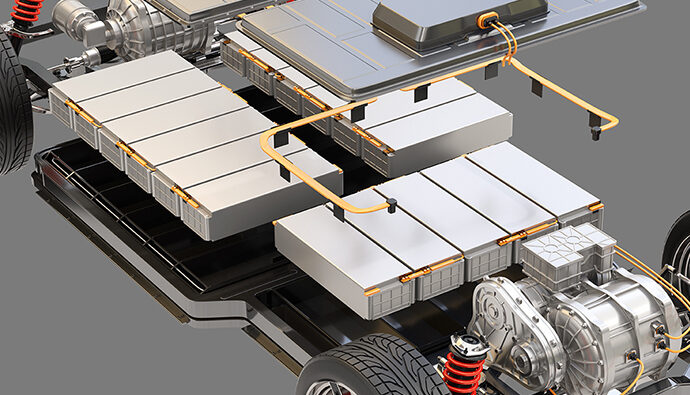

Lithium-Ion Battery Manufacturing Can Include:

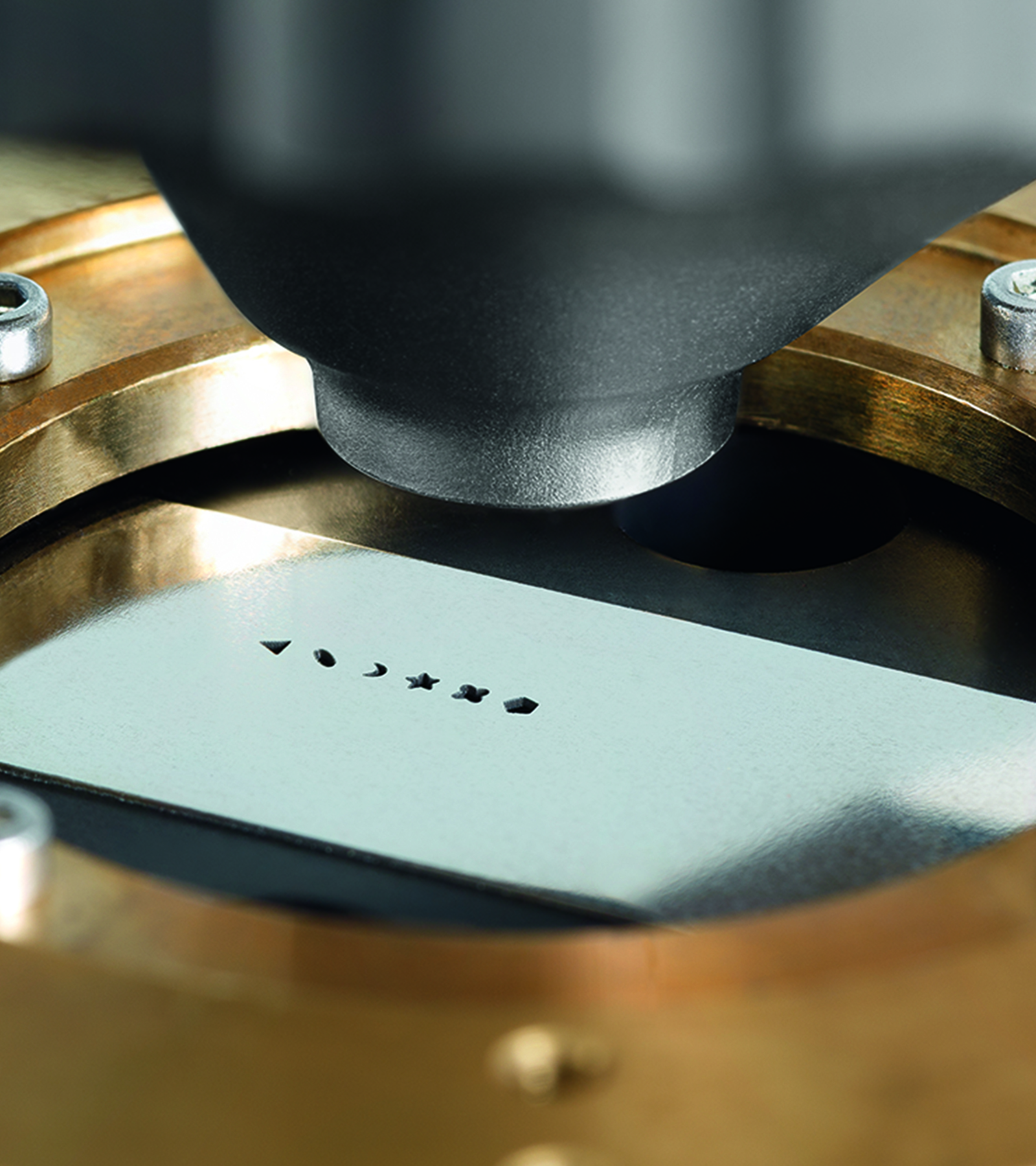

- Micron level precision for cutting, drilling, perforating, and surface processing applications

- Complete processing area and pattern flexibility with 2-axis, 3-axis, multi-axis, and polygon laser scan heads

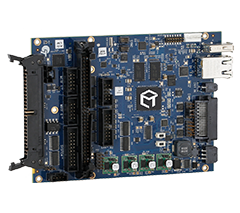

- Flexible system integrations incorporating critical core laser system components, including galvanometers, galvanometer sets, resonant scanners, servo drivers, and multiple laser sources

- Powerful laser controller and software solutions incorporate proprietary algorithms to deliver controls and features for application-specific jobs