Lithium-Ion Battery Manufacturing

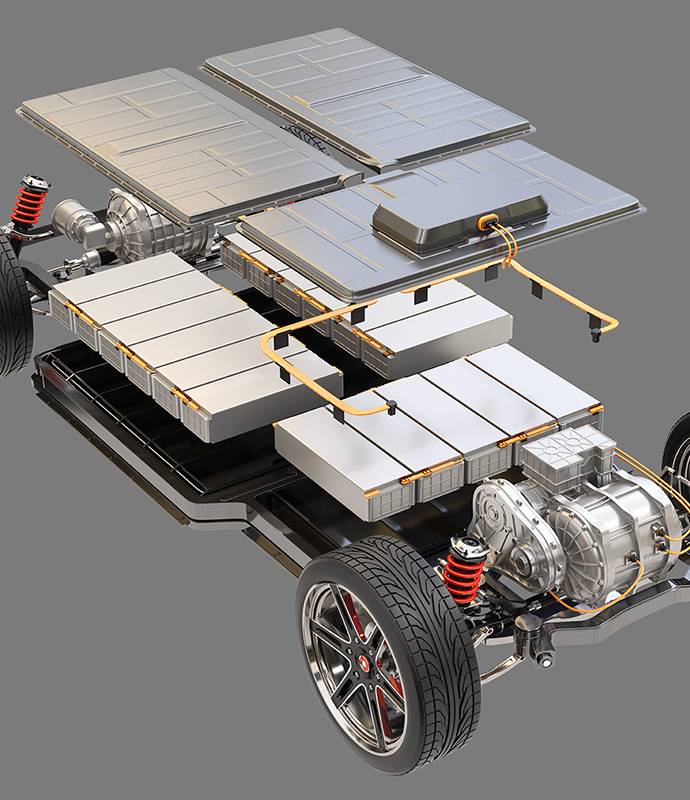

Advancements in laser beam delivery, controllers, software and laser sources deliver greater cost efficiency with added flexibility to pursue new battery designs.

About Lithium-Ion Battery Manufacturing

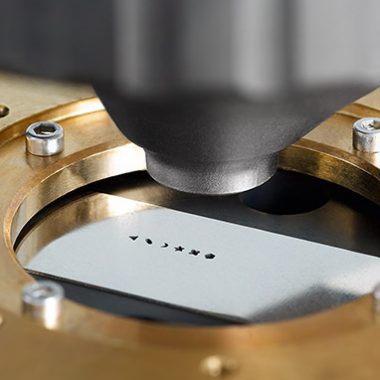

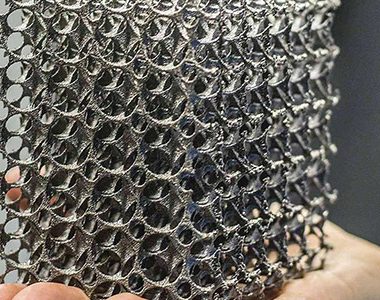

Laser processing offers higher levels of precision, flexibility, and adaptability for cutting, welding, surface structuring, and cleaning processes as compared to traditional methods. Advancements in laser sources, beam delivery, controllers/software deliver cost efficiencies and flexibility enabling battery manufacturers to pursue new designs.

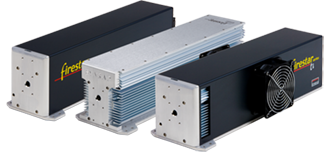

As demand for lithium-ion batteries grow Novanta is in a unique position to work with manufacturers, offering laser processing solutions at both the component level and purpose-built sub-system solutions. Our well-know product brands include Cambridge Technology beam delivery systems, Laser Quantum solid state continuous wave and ultrafast lasers, and Synrad high performance CO2 lasers that deliver:

- Micron level precision for cutting, drilling, perforating, and surface processing applications

- Complete processing area and pattern flexibility with 2-axis, 3-axis, and multi-axis, and polygon scan heads

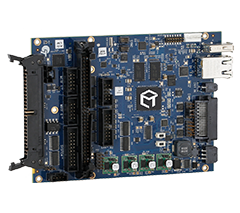

- Flexible system integration incorporating critical core laser system components, including galvanometers, galvanometer sets, resonant scanners, servo drivers, and multiple laser sources

- Powerful laser controller and software solutions that incorporate proprietary algorithms to deliver controls and features for application-specific jobs

Request an Application or Material Test

Request an Application or Material Test