Our Laser Beam Steering Solutions

Discover industry-leading laser beam steering components and systems that transform your organization's manufacturing processes at Novanta Precision Manufacturing. Experience enhanced control over beam direction with advanced laser beam steering technology. View our comprehensive portfolio of scan heads, galvanometers, XY galvanometer sets, precision mirrors, resonant scanners, servo drivers, and polygon scanning solutions.

Scan Heads

Complete integrated systems combining multiple components for precise beam positioning.

スキャン・ヘッド

XYガルバノメーター・セット

Coordinated galvanometer pairs for precise 2-axis beam positioning.

XY Galvanometer Sets

Resonant Scanners

Ultra-fast scanning capabilities for high-throughput applications.

CRS, Resonant Scanners

サーボ・ドライバー

Advanced digital and analog servo control systems for precise motor control.

Servo Drivers

How Laser Beam Steering Technology Works

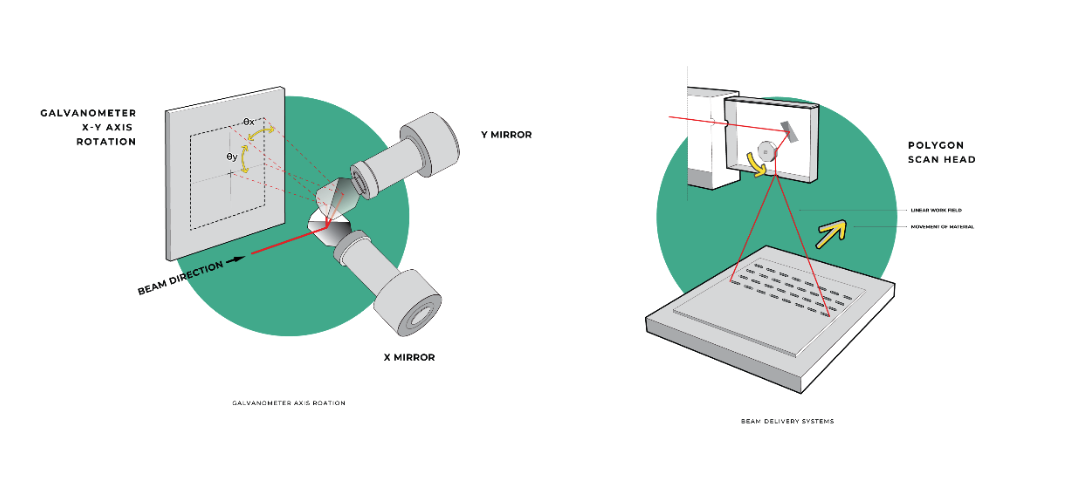

Laser beam steering solutions are used to direct a laser’s output beam to the target area with extreme precision, enabling the laser source to remain stationary. Optical components such as specialized mirrors combined with high-precision, high-speed galvanometers, resonant scanners, or polygon scanners change the angle of the laser’s output beam, enabling extremely fast and precise positioning for laser processing.

Modern beam steering components and systems measure positioning accuracy in micrometers (µm), enabling accurate, high-level laser processing quality. Laser beam steering solutions are typically available as individual components, modules that combine individual components, and laser scanning heads that integrate components and modules into a single unit.

view technical information

Laser Beam Steering Applications

Versatile technology solutions for diverse industrial manufacturing processes

Laser Coding and Marking

High-precision marking for traceability and branding applications.

Precision Laser Cutting

Ultra-precise cutting with minimal material waste and exceptional edge quality.

Laser Engraving

Detailed engraving for decorative and functional surface modifications.

レーザー溶接

High-strength joining of materials with precise heat control.

Laser Drilling

Precise hole creation in various materials and thicknesses.

3Dプリンタ

Advanced 3D printing with exceptional layer precision and quality.

材料加工

Advanced material modification and surface treatment processes.

Surface Scanning

Quality control inspection with sub-micrometer accuracy.

Research & Development

Advanced research applications requiring precise beam control.

Why Novanta Precision Manufacturing?

At Novanta Precision Manufacturing, we've been developing market-leading laser beam steering solutions, laser sources, control software, and user software for over 50 years. We favor an engineer-to-engineer approach, working with manufacturers' OEMs to design and build reliable, high-performance laser beam steering components to transform your operations.

50+ Years Experience

Decades of expertise in laser technology and precision manufacturing solutions.

Engineer-to-Engineer

Direct collaboration with technical teams for optimal solution design.

Applications Testing Labs

Comprehensive testing facilities to validate performance before deployment.

よくある質問

Advanced laser beam steering solutions deliver many advantages in manufacturing environments:

- Enables delivery of the laser beam to create highly precise text, graphics, through-cut patterns, cutting patterns at varied depths

- Enhanced finished product quality

- Enables late-stage alterations and on-the-fly changes

- Processing flexibility and increased efficiency

- Create complex, intricate designs not achievable with traditional equipment

- Reduced material waste and lower operating costs

- Non-contact processing maintains sanitary environment

- Supports sustainability with low energy consumption

Novanta offers several beam steering technologies for industrial and medical applications:

- Resonant Scanners: Uses vibrating mirror oscillating at set frequency, acting like a tuning fork

- Galvanometers: Uses interaction between magnetic field and electrical current to oscillate mirrors

- Servo Drivers: Digital and analog technology to control position of scanners and galvanometers

- Scanning Heads: Combines 2+ galvanometers with high-precision mirrors and focusing lens

- Polygon Scanners: Multiple mirrors mounted on wheel at precise angles for linear sweeping motion

The exact cost depends on your precise requirements and specifications. Starting prices:

- Resonant scanners: Starting around $3,800

- Galvanometers: Starting around $800

- Scan heads: Starting around $2,210

- Polygon scanners: Starting around $6,000

- Contact our team for a tailored quote based on your specific application requirements.