CO₂ Lasers

プロセスの柔軟性を高め、運用コストを削減します

Discover Precision CO₂ Lasers

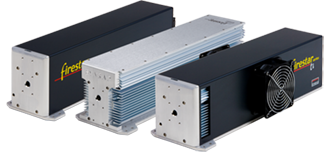

Experience extreme precision and reliability with industry-leading carbon dioxide (CO₂) lasers and systems by Novanta Precision Manufacturing. Our versatile CO₂ lasers minimize downtime to enhance manufacturing productivity and support efficiency, benefiting your bottom line. With over 50 years’ experience as a CO₂ laser manufacturer, we’ve developed deep proprietary expertise and favor an engineer-to-engineer approach to build reliable, high-precision CO₂ laser solutions for original equipment manufacturers (OEMs) across a broad range of industries.

p-Series, 100-400 Watt Pulsed CO₂ Lasers

Learn More

48 Series - 8-10 Watt CO₂ Lasers

Learn More

f Series - 200 Watt CO₂ Lasers

Learn More

ti Series - 60-100 Watt CO₂ Lasers

Learn More

vi Series 30 & 40 Watt CO₂ Laser

Learn More

i Series - 400 Watt CO₂ Lasers

Learn MoreReady to find out more about our CO₂ lasers?

About Novanta CO₂ Lasers

What is a sealed tube CO2 laser?

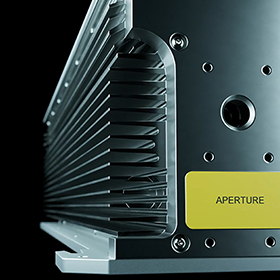

A sealed tube CO₂ laser is a favored technology for a broad range of applications due to its versatility, reliability, and efficiency that can improve productivity. Sealed tube CO₂ lasers generate a concentrated beam of light at specific wavelengths through the excitation of a gas mixture within a tube, making these self-contained modules that can be integrated into larger laser processing systems. The gas mixture is energized by an electrical discharge, causing the CO₂ molecules to emit a beam of infrared light. The beam of light is directed to the target material via secondary beam delivery systems to perform a variety of laser processing interactions, including cutting, marking, engraving, and ablation on a range of materials.

Novanta CO₂ lasers enable non-contact material processing, eliminating tool wear and maintenance costs associated with traditional processing technologies, making them an efficient, cost-effective solution.

Novanta CO₂ laser features

- High reliability for long operating lifetimes

- Low maintenance requirements minimize operating expenses

- Available in 9.3 µm, 10.2 µm, and 10.6 µm wavelengths for a broad range of materials and processing capabilities

- Multiple power level options from 10 W average power to 1 kW pulse power to optimize system configuration

- Air, fan, and water-cooling options for flexible integration options

- Seamless integration with Novanta laser beam delivery systems for unique laser processing solutions

- Serviceable platforms that extend operational lifetimes

- Suitable for high-speed and high-volume production

What can Novanta CO₂ lasers be used for?

Materials

- レーザー切断

- ポリマー

- Acrylic

- 木材

- 紙

- 段ボール

- セラミック

- ガラス

- テキスタイル

- 皮革

- フォイル

- Thin Metals

- Multi-Layer Materials

- Some Composite Materials

アプリケーション

レーザー切断

CO₂ lasers are frequently used for cutting an extensive range of materials and offer the ability to control the cut edge finishesLaser marking and coding

CO₂ lasers can be used to applyies permanent serial numbers, expiration dates, certifications, logos, bar codes, QR codes, 2-dimensional and graphical codes to support traceability, verification, and authenticationLaser engraving

CO₂ lasers can producecreate detailed, intricate designs on a variety of surfaces, for both industrial and aesthetic purposesLaser welding

CO2 lasers can be used to create strong, clean welds on metal and polymers with exacting precision and lasting durabilityLaser Drilling and Perforating

CO2 lasers can make thru-holes in varied shapes and sizes with micron level precision to promote connectivity, enable easy-open packaging, allow ventilation, and create unique graphicalLaser ablation

CO2 lasers can remove insulation, surface coatings, residual materials, and oxidation with extreme precision to enable additional processing steps on clean surfacesLaser surface treatment

CO2 lasers are used to apply textures to surfaces and activate specialized coatings for unique product finishesPost-production processing

CO2 lasers are used for a variety of applications after production of dimensional products is completeよくある質問

There are many advantages of using CO₂ lasers in industrial settings, including:

- Versatility – CO₂ lasers can perform a broad range of processing operations

- High Precision – theseCO₂ lasers deliver micrometer level precision

Consistency – CO₂ lasers are digitally controlled and deliver repeatable results - Efficient – CO₂ lasers minimize downtime and waste to improve productivity

- Zero-Touch – CO₂ lasers enable the processing of sensitive materials

- Extreme Detail – this type of CO₂ lasers can create

CO₂ laser technology is used in the manufacture of a wide range of products and parts, including:

- Packaging, both flexible and rigid

- Automotive and EV parts, including lithium-ion batteries

- 航空宇宙コンポーネント

- Electronic devices

- Micro components

- Fashion and textiles

- Solar cell components

- Architectural glass and glass products

- Wood products

- Electric motor components

- 3D printed polymer products

- Fractional skin resurfacing devices

- Dental procedures and devices

- Pharmaceuticals

- Wire and cable

- Person

There are several key differences between CO₂ lasers and fiber lasers, including:

- CO₂ lasers use a gas mixture and an electrical discharge to generate the laser beam, while fiber lasers use an optical fiber with rare-earth elements and a laser diode pump source.

- All lasers generate a beam at a specific wavelength;, fiber lasers generate lasers at wavelengths from 780 nm to 2200 nm, while CO2 lasers generate lasers at wavelengths from 9.3 µm to 10.6 µm.

- CO2 lasers have a longer wavelength and are better suited for processing materials like wood, plastics, paper, rubber, fabrics, leather, some composites, and nonferrous metals.

The cost of CO₂ lasers will vary depending on your exact requirements, with our prices starting at ~$3,400, with discounts for volume orders. Once installed, CO₂ laser systems can be a cost-effective choice, as there are no additional costs for consumables, while minimal maintenance and manual intervention is required, keeping labor costs low.