Laser Material Processing

Solutions for complex laser material processing challenges

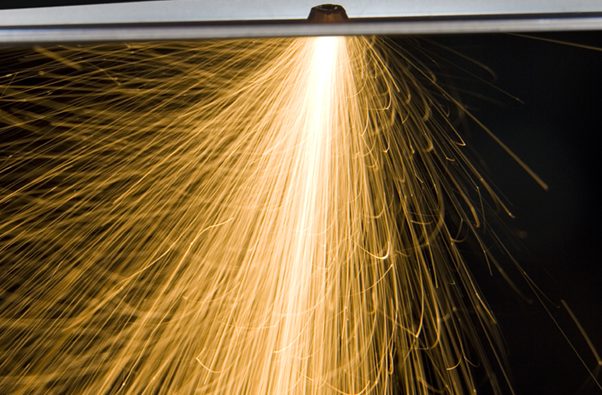

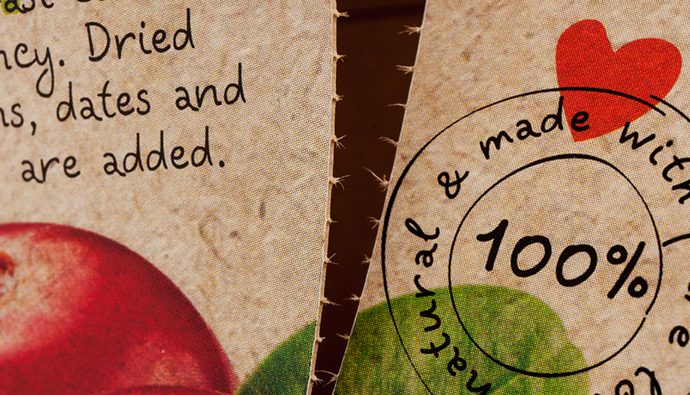

Mark industrial components, products and packing using advanced laser material processing techniques, including cutting, scoring, engraving and ablation. Material processing with laser solutions enables a high level of precision, consistency and quality.

✔ Precision solutions

✔ Highly versatile

✔ Repeatable quality results

✔ Powering tomorrow’s industries

Request an Application or Material Test

Request an Application or Material Test

What is Laser Material Processing?

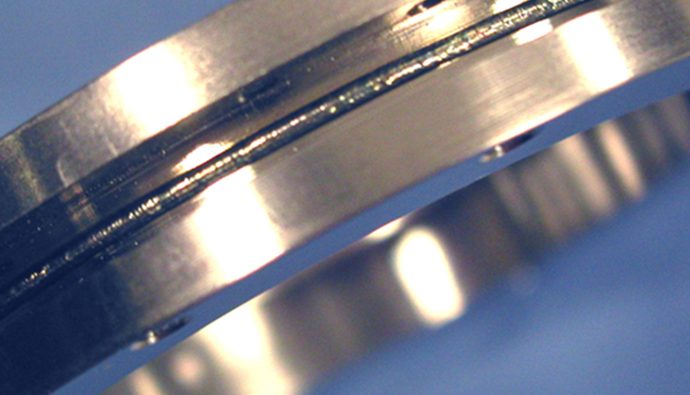

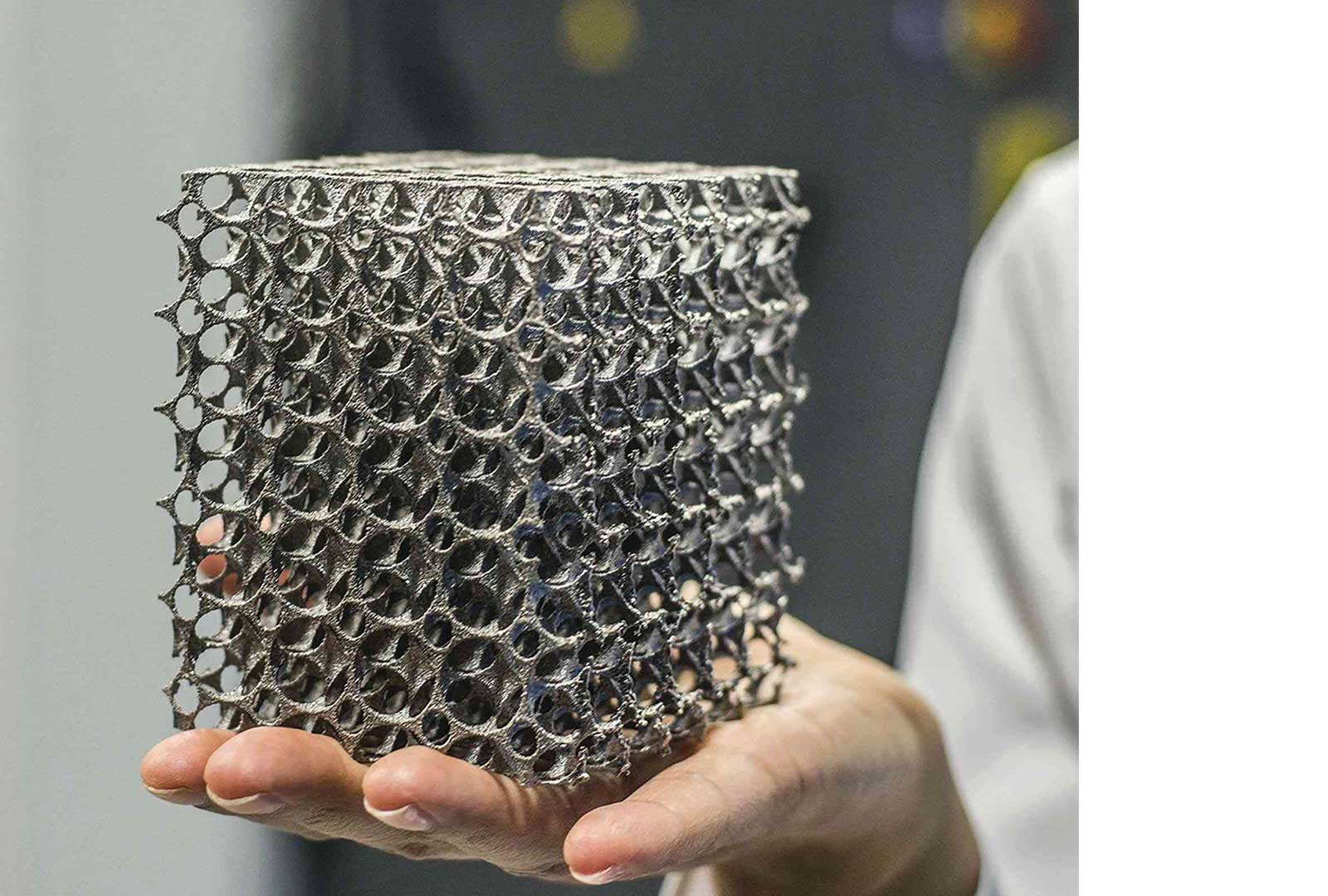

Laser material processing can refer to a variety of laser applications, including laser marking and coding, cutting, scribing, laser welding and laser drilling. Undertaking material processing with laser technology enables precision laser marking across a wide range of materials from plastic to metals to leather and cardboard.

Laser material processing is favored for its fast turnaround and versatility, allowing organizations to quickly adapt to producing new designs or meeting the demands of changing industry regulations without compromising quality.

Businesses seeking material processing solutions may find the choice of available materials, finish options and feature requirements overwhelming, but laser material processing systems provide a cost-effective, efficient option. With a laser processing system, the same piece of equipment will be able to perform multiple application processes, saving time, money and

Advantages of Laser Material Processing

The benefits of material processing with laser systems over other methods include:

- Fast: lasers can operate at high speeds for fast material processing that can quickly adapt to new designs or meet new industry regulations as required

- High precision: lasers provide an extremely high level of precision that simply can’t be achieved with other material processing methods. Novanta Photonics’ laser solutions are designed to ensure precision performance, whether that’s for intricate engravings, precise scoring or crisp, laser-cut edge forming

- Versatile: lasers can be used on a wide variety of materials, including metals, plastics, glass, ceramics, leather, textiles, paper, cardboard, and more

- Consistent: laser material processing enables repeatable results, as the system can be programed to create the same marks or codes over and over again for guaranteed precision and consistency

- Non-contact processing: laser processing eliminates the risk of contamination or wear and tear, as the laser does not touch the material during processing. This makes lasers ideal for processing delicate materials like glass and ceramics

- Improved surface finish: laser material processing often results in a smoother finish compared to traditional methods, reducing the need for additional finishing processes

- Reduced heat-affected zones: lasers concentrate energy on a small area, minimizing the heat-affected zone, reducing thermal distortion of the material

- Cost-effective: as the same laser system can be used to perform multiple material processing tasks, this can save time, labor and associated costs, helping to reduce spend

Why Choose Novanta Photonics for Laser Material Processing?

With over 35 years’ experience providing laser material processing components and subsystems to customers across the globe, Novanta Photonics is the reliable choice for high-precision, cutting-edge laser systems. Expand your organization’s flexibility and embrace new, more efficient material processing laser solutions.

Laser Material Processing Applications

レーザー・マーキングとコーディングには以下が含まれます。

- 英数字テキスト

- 日付とシリアル化コード

- データ・マトリックスとQRコード

- ロゴ

- グラフィックス

- パターン