Precision Laser Marking for Automotive Components

Challenges in Marking for Automotive Manufacturing

Automotive manufacturers face increasing demands for component traceability, quality control, and supply chain management. Traditional marking methods struggle with precision requirements, production speed demands, and the need for permanent, readable marks on complex curved surfaces.

Key challenges include maintaining marking quality on various materials, achieving micron-level repeatability, managing thermal effects on sensitive components, and integrating marking systems into high-speed production lines while ensuring reliable 24/7 operation.

How Novanta Solves Automotive Marking Challenges

Our high-speed galvo scan heads paired with advanced control software enable precise marking on curved automotive surfaces with minimal distortion. The VERSIA 2-axis scan head combines analog and digital technologies for optimal performance.

With ultrafast laser technology, we achieve black marking on metals while maintaining corrosion resistance. Our integrated sub-systems include laser sources, beam delivery, scan heads, and control software – all factory-aligned with a 2-year comprehensive warranty.

Benefits of Novanta's Laser Marking Systems

High-Speed Processing

Micron-level accuracy with 3-4x faster marking than traditional engraving systems

Seamless Integration

Compact design with industry-standard inputs for easy OEM platform integration

Real-Time Control

Advanced feedback systems with precise beam positioning for curved surfaces

Metal Optimization

Specialized for automotive metals, plastics, and composite materials

Scalable Production

Reliable 24/7 operation designed for high-volume automotive manufacturing

Proven Results in Automotive Manufacturing

A leading automotive parts manufacturer implemented Novanta’s VERSIA scan head system for Direct Part Marking (DPM) applications, achieving a 30% reduction in cycle time while maintaining perfect traceability for regulatory compliance.

Recommended Products for Automotive Marking

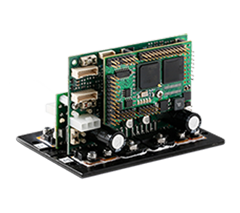

VERSIA 2-Axis Scan Head

Breakthrough analog + digital solution for marking and coding with advanced features

Learn More

Lightning II Digital Scan Head

Full digital 2-axis system with 24-bit resolution and closed-loop feedback

Learn More

62xxK & 83xxK Galvanometers

Fastest motor speeds in the industry with long-term stability

Learn More

vi Series CO2 Lasers

30-40 Watt compact lasers with stable power output for consistent marking

Learn Moreよくある質問

Our laser marking systems work on a wide range of automotive materials including metals (steel, aluminum, titanium), plastics, composites, and glass. Ultrafast laser technology enables black marking on metals while maintaining corrosion resistance properties.

Advanced galvo scan heads enable precise beam positioning on curved automotive surfaces with minimal distortion. The high-speed galvo systems provide 3-4x faster marking than traditional methods while maintaining micron-level accuracy.

Our systems support all automotive traceability requirements including serial numbers, date codes, batch marking, barcodes, QR codes, and Direct Part Marking (DPM) for machine-readable identification throughout the product lifecycle.

VERSIA scan heads feature IP54 rated enclosures and are designed for reliable 24/7 operation. With over 50 years of experience, our systems are built for demanding automotive manufacturing conditions with comprehensive warranty support.

Our compact, lightweight design includes intuitive industry-standard inputs and outputs for easy machine integration. We provide engineer-to-engineer collaboration and Applications Testing Labs for proof-of-concept development.