Laser Drilling

Create precise, consistent holes using advanced laser drilling solutions by Novanta Photonics. Process metals, ceramics, plastics and more with precision control over hole diameter, taper, depth, placement, and more. Precision material processing Drill a wide variety of materials High quality and repeatability Cutting-edge technology

What is laser drilling?

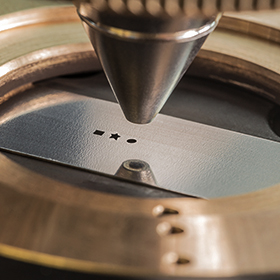

Laser drilling is a digitally controlled, non-contact method of precision processing that uses a focused laser beam to create extremely precise, consistent holes of various sizes on tough and sensitive materials alike.

Laser beam drilling provides exacting control over hole shape, size, taper, depth and placement, all with excellent repeatability. This technology enables the creation of intricate patterns, shapes and perforations with minimal waste and debris.

Why choose Novanta Photonics' laser drilling systems?

We’ve been providing laser drilling components to clients across the globe for almost four decades. Businesses around the world use our cutting-edge solutions to develop advanced laser drilling technology.

Our systems require high peak power to create high aspect ratio holes while minimizing heat impact. We match scan heads, XY-gantries, control software and laser sources to ensure accurate, repeatable results at the desired speed

Advantages of Laser Drilling

High Precision

Extreme accuracy when creating micro and intricate holes with high depth-to-diameter ratio control

Enhanced Efficiency

High repeatability of automated laser drilling machines create multiple holes quickly and consistently

Material Versatility

Compatible with metals, foams, plastics, composites, and ceramics across various industries

Zero Contact

Non-contact processing extends tool lifespan and reduces risk of material warping or distortion

Minimal Waste

Highly precise nature means minimal waste compared to traditional drilling techniques

Cost-Effective

Increased efficiency reduces labor costs while eliminating need for drill bit replacement

よくある質問

Laser drilling is a digitally controlled, non-contact method that uses focused laser beams to create extremely precise, consistent holes. It provides exacting control over hole shape, size, taper, depth and placement with excellent repeatability, using high peak power lasers with minimal heat impact.

There are four main types: Single pulse drilling for small precise holes, Percussion drilling using multiple pulses, Trepanning for larger diameter clean holes via circular cutting, and Helical drilling for deep spiral paths with smooth finishes.

Laser drilling serves aerospace (cooling/venting holes), automotive (filters, nozzles), electronics (circuit boards, wafers), food/pharmaceutical packaging (ventilation), medical devices, textiles, and jewelry manufacturing applications.

Key advantages include high precision for micro and intricate holes, enhanced efficiency through automation, versatility across multiple materials, zero-contact processing, minimal waste generation, and cost-effectiveness through reduced labor and no tool replacement needs.

Laser drilling technology is compatible with a wide selection of materials including metals, foams, plastics, composites, ceramics, and other tough or sensitive materials across various industrial applications.